” Since the beginning the Company’s high quality HDPE pipes fittings

Our key to success roots from the trust we receive from our customers. This confidence from customers is the reason why all products beneath the TAP brand and OEM products are accepted from the HDPE pipe system industry as one of South East Asia’s best manufacturers. The Company’s reputation has resulted in imports to over 15 countries overseas

Click image for details

▼

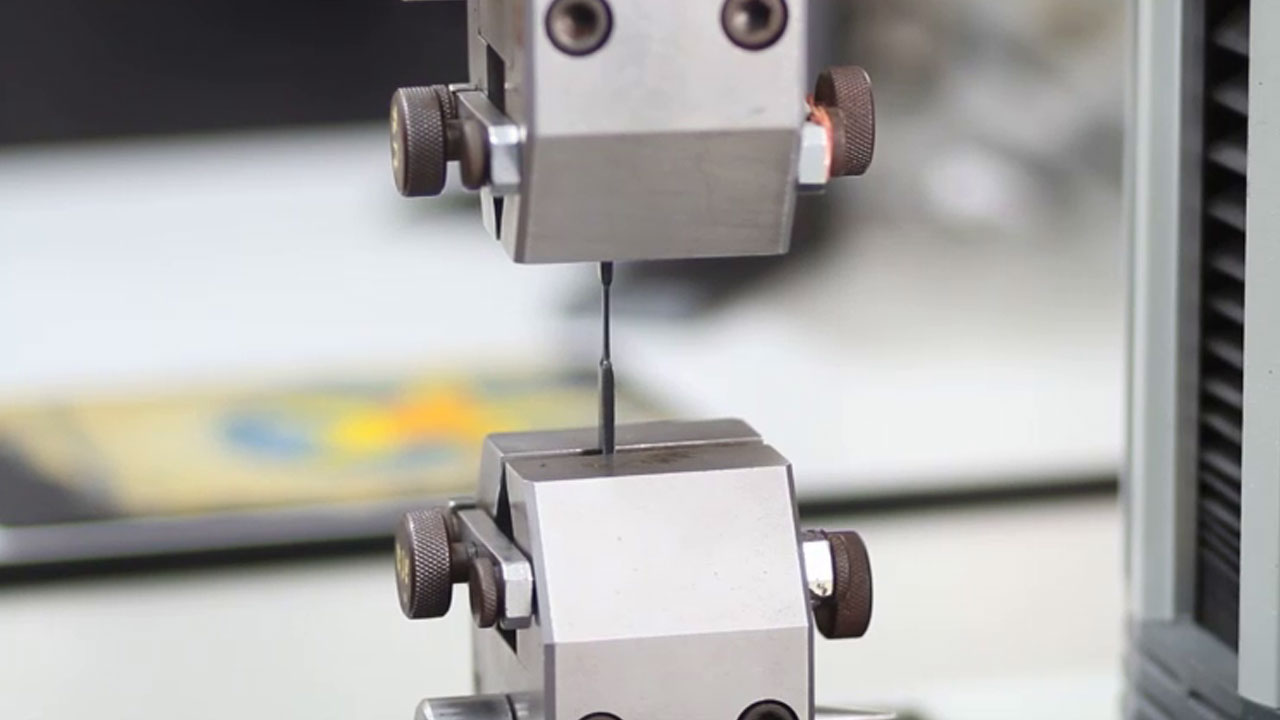

The Tension Test

The tension test is carried out using the Universal Testing Machine (UTM), one of the basic mechanical tests to control the quality of raw material pellets, HDPE pipe products along to knit line strength. Testing methods meet international standards; ASTM D 628 and ISO 527-2 for plastic materials, ISO 6259 pipe tension test and ISO 13953 HDPE knit line test, for instance. Beneficial information from these tests include

- The tensile strength at yield

- The tensile strength at break

- The percentage (%) of elongation at break

The Internal Pressure Creeping Test

The internal pressure creeping test of HDPE pipes is carried out using the Hydrostatic Testing Machine, a crucial mechanical property test that builds positive reputation towards our products’ quality. This is because the test qualifies HDPE pipe quality, meeting international standards used in referencing to the manufacturing process such as TIS 982, ISO 4427, BS EN 12201, AS/NZS 4130, DIN 8074/75 and so on. In this test, the pressure and temperature within the pipe will be stably controlled at a certain value. During this mentioned period, the pipe must not break, leak or fracture within a determined time

The Longitudinal Reversion Test

The longitudinal reversion test for HDPE pipes is carried out using a glycerin oil tank. This test is used to test physical changes or usage durability which causes longitudinal shrinkage and expansion from conditional changes in temperature. Test methods meet ISO 2505 standards. The pipe will be heated to a temperature as high as 110℃ for 30 minutes. Afterwards, the length will be measured once again. The length measured after the longitudinal reversion test must not differ exceeding 3% from the length measured before the test

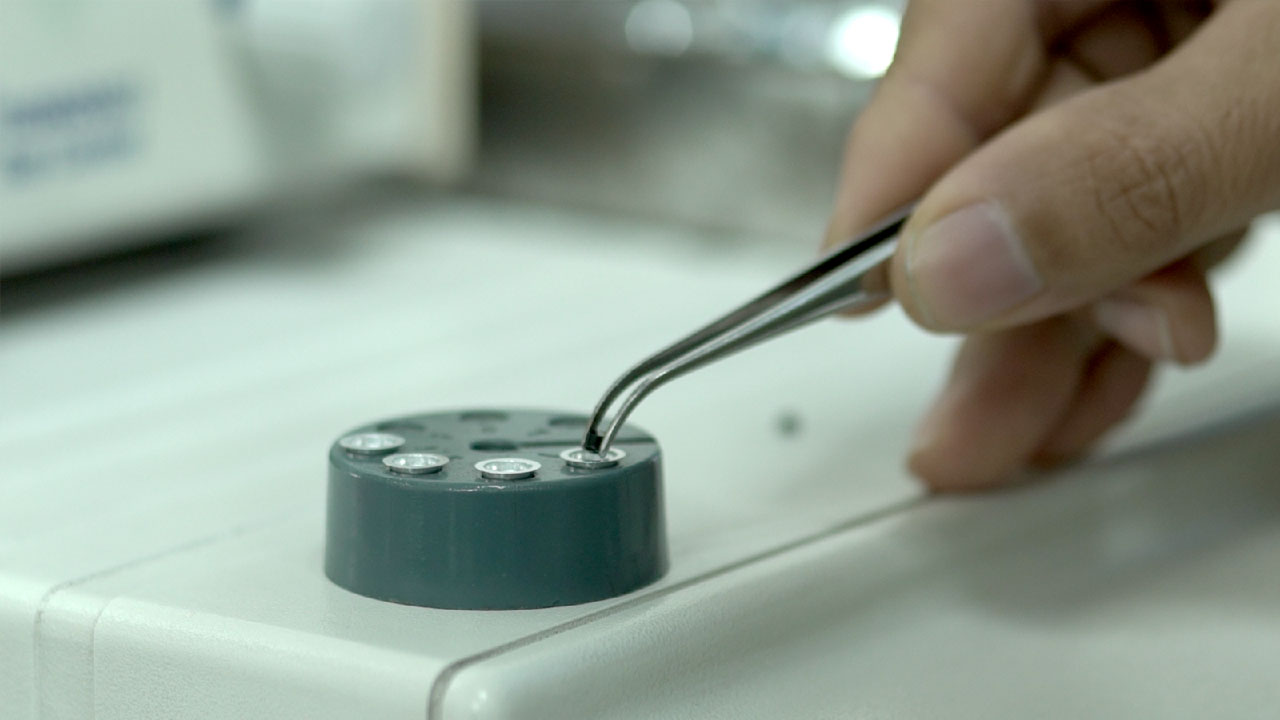

The Oxidation Induction Time test

The Oxidation Induction Time (OIT) test is carried out using a Differential Scanning Calorimeter (DSC). This is to test the basic thermal properties to prevent oxidation in HDPE pipes. This test crudely indicates actual usage timespan and durability towards different conditions. Testing methods meet standards such as ISO 11357 or ISO/TR 10837 at a temperature of 200 or 210℃, the OIT must not be lesser than 20 minutes

The Melt Flow Rate Test

The Melt Flow Rate (MFR) is tested using the melt flow indexer machine. Testing methods meet ISO 1133 standards, a thermal property test for plastics. The test indicates the flow behavior of raw material pellets after being heated, which is applied for considering the suitable temperature for production. The process controls the quality of raw material pellets. If the MFR value falls within suitable criteria, this will indicate regularity and good quality of raw materials used in the manufacturing process. HDPE pipe product tests will also stipulate production efficacy, resulting in strong, durable, quality products with long usage timespan

The Ultrasonic Flaw Test

Flaws in pipe products and accessories are detected using the Ultrasonic Tester machine