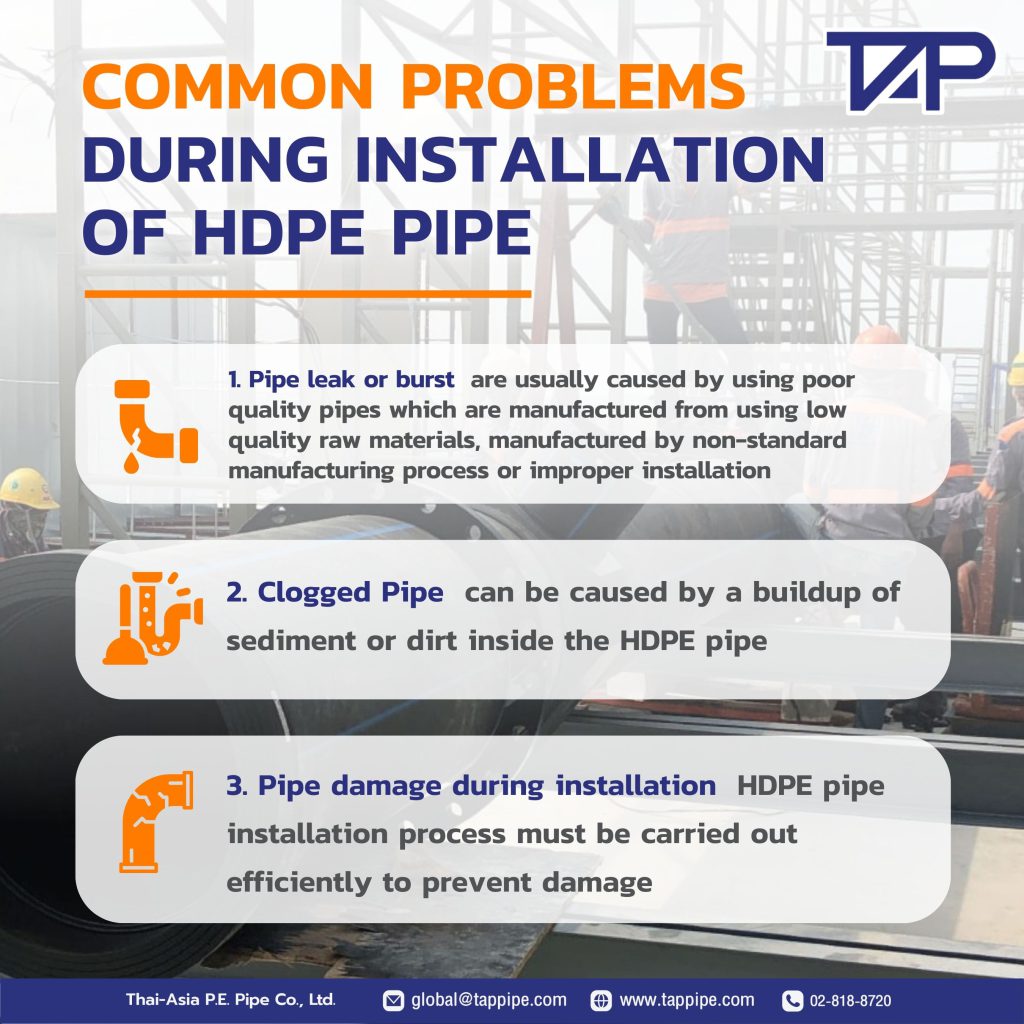

- Pipe leak or burst : Leaking or bursting of HDPE pipes are usually caused by using poor quality pipes which are manufactured from using low quality raw materials or manufactured by non-standard manufacturing process. Also pipe leak and burst may occur due to improper installation where the pipes are unable to withstand the pressure. Therefore, it is advisable to use HDPE pipes only from reliable manufacturers.

- Clogged Pipe : Blockages in pipes can be caused by a buildup of sediment or dirt inside the HDPE pipe, which can result in unsmooth flow of water or chemicals. Therefore, regular maintenance should be done to ensure that there is no accumulation of sediment or dirt inside the pipe.

- Pipe damage during installation: HDPE pipe installation process must be carried out efficiently to prevent damage such as preparing the soil surface to be smooth, etc.

To reduce potential problems, one should consider to buy HDPE pipes from a high quality and reliable manufacturer, selecting a suitable installation method for the project site and most importantly, one should follow the instructions recommended in the standards for HDPE pipes.

Comments are closed.