ABOUT HDPE PIPES

THAI-ASIA P.E. PIPE CO., LTD. (TAP)HIGH QUALITY HDPE PIPES AND FITTINGS MANUFACTURER

WHAT ARE HDPE PIPES?

HDPE pipes are pipes made from High-Density Polyethylene, a thermoplastic material produced by polymerization process under high pressure and temperature. Pipes produced from HDPE are strong and durable and can withstand high pressure. HDPE pipes are also chemical resistant.

1. Strong and durable

HDPE pipes are strong, durable and can withstand high pressures.

HDPE pipes are strong, durable and can withstand high pressures.

2. Light weight and high flexibility

HDPE pipes are light weight and have high flexibility which is suitable for installation.

HDPE pipes are light weight and have high flexibility which is suitable for installation.

3. Chemical resistant

HDPE is chemical resistant and is commonly used in many applications such as potable water supply pipes, drainage and sewerage pipes, electrical conduits, mining pipes and many more.

HDPE is chemical resistant and is commonly used in many applications such as potable water supply pipes, drainage and sewerage pipes, electrical conduits, mining pipes and many more.

4. Environmental stress crack resistant

HDPE pipes are suitable for installation in extreme environmental conditions with operating temperature of -40°C to 80°C.

HDPE pipes are suitable for installation in extreme environmental conditions with operating temperature of -40°C to 80°C.

5. Ultraviolet (UV ) resistant

HDPE pipe can withstand UV rays and is suitable for outdoor and above ground installations.

HDPE pipe can withstand UV rays and is suitable for outdoor and above ground installations.

1. Strong and durable

HDPE pipes are strong, durable and can withstand high pressures.

HDPE pipes are strong, durable and can withstand high pressures.

2. Light weight and high flexibility

HDPE pipes are light weight and have high flexibility which is suitable for installation.

HDPE pipes are light weight and have high flexibility which is suitable for installation.

3. Chemical resistant

HDPE is chemical resistant and is commonly used in many applications such as potable water supply pipes, drainage and sewerage pipes, electrical conduits, mining pipes and many more.

HDPE is chemical resistant and is commonly used in many applications such as potable water supply pipes, drainage and sewerage pipes, electrical conduits, mining pipes and many more.

4. Environmental stress crack resistant

HDPE pipes are suitable for installation in extreme environmental conditions with operating temperature of -40°C to 80°C.

HDPE pipes are suitable for installation in extreme environmental conditions with operating temperature of -40°C to 80°C.

5. Ultraviolet (UV ) resistant

HDPE pipe can withstand UV rays and is suitable for outdoor and above ground installations.

HDPE pipe can withstand UV rays and is suitable for outdoor and above ground installations.

Strong and durable

Light weight and high flexibility

Chemical resistant

Environmental stress crack resistant

Ultraviolet (UV) resistant

Previous

Next

Our Supplier

Our Standard

Applications for HDPE pipe

Advantages of HDPE pipes

- easy to install.

- Controllable Lengths

(Coils up to 500 Meter, Lengths up to 21 Meter) - Up to 50 years of lifetime

- High Chemical Resistance

- Flexible for all underground conditions

(E.g. Earthquake resistance)

TYPES OF ASSEMBLY FOR HDPE PIPE

There are several types of assembly for HDPE pipesElectro-Fusion Welding Method.

Electro-Fusion is a method for joining HDPE and other plastic pipes by passing electric current to the conductive coil embedded in the fittings also called Couplings. This causes the pipes and Fittings to melt homogenously creating strong joints which can withstand high pressure.

Butt-Fusion Welding Method.

Butt-Fusion welding is a method for joining High Density Polyethylene (HDPE) pipe or fittings together where both ends are heated using a heating plate with constant temperature and pressure resulting in pipe and fittings to weld together homogeneously. Butt-Fusion welding technique is commonly used in gas pipelines and water distribution systems.

Previous

Next

TYPES OF INSTALLATION FOR HDPE PIPE

There are several types of installation for HDPE pipesInstalling HDPE pipes using the Horizontal Directional Drilling (HDD) method.

HDPE HDD installation refers to the installation of High-Density Polyethylene (HDPE) pipes using the Horizontal Directional Drilling (HDD) method. Horizontal Directional Drilling (HDD) is a trenchless method of installing underground utilities, including pipelines, without the need for open-cut trenches. This technique is commonly used when traditional excavation or trench installation methods

Installing HDPE pipes using the Trench Installation method

HDPE trench installation refers to the process of installing High-Density Polyethylene (HDPE) pipes within a trench for various applications, such as water supply, drainage, or conduit systems. HDPE pipes are known for their durability, flexibility, and resistance to corrosion, making them a popular choice for underground installations.

Previous

Next

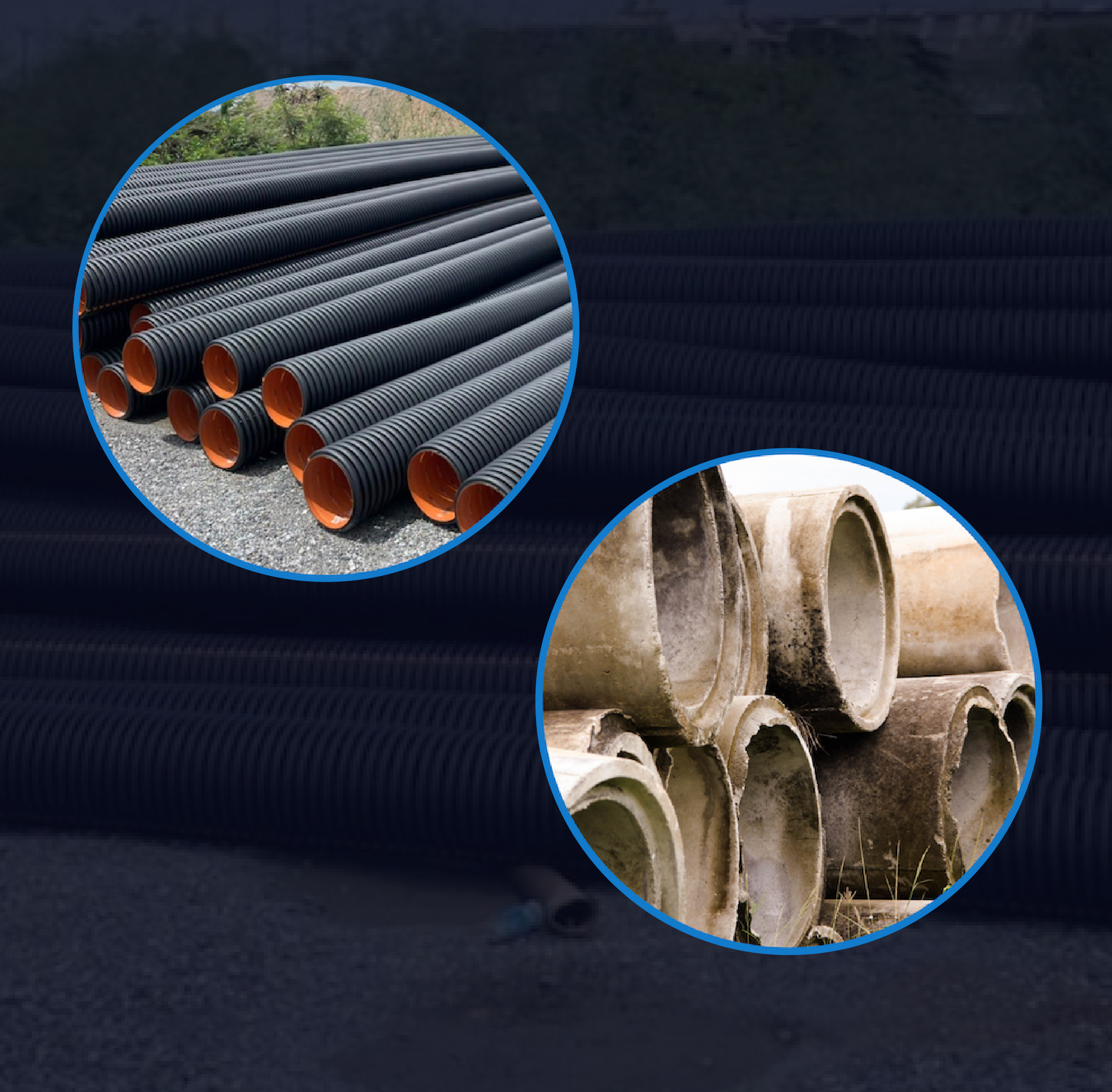

HDPE Corrugated pipe VS Concrete pipe

1. LIGHT WEIGHT

HDPE pipe is lightweight when compared with concrete pipes

HDPE pipe is lightweight when compared with concrete pipes

2. FLEXIBLE AND HIGH LIQUID FLOW

HDPE pipe has good flexibility and easy to install when compared to concrete or reinforced concrete pipes. In addition, the inner surface of the HDPE pipe is smooth, resulting in a high flow rate of water.

HDPE pipe has good flexibility and easy to install when compared to concrete or reinforced concrete pipes. In addition, the inner surface of the HDPE pipe is smooth, resulting in a high flow rate of water.

3. CHEMICAL RESISTANCE AND CORROSION RESISTANCE

HDPE pipes are resistant to chemicals and corrosion when compared with concrete pipes. Therefore HDPE pipes are suitable to use in chemical and acidic environments.

HDPE pipes are resistant to chemicals and corrosion when compared with concrete pipes. Therefore HDPE pipes are suitable to use in chemical and acidic environments.

4. ENVIRONMENTAL FRIENDLY

HDPE pipes are considered more environmentally friendly than concrete pipes in many factors like energy consumptions, carbon emissions, resource usage, transportation, installation and its Lifecycle of more than 50 years.

HDPE pipes are considered more environmentally friendly than concrete pipes in many factors like energy consumptions, carbon emissions, resource usage, transportation, installation and its Lifecycle of more than 50 years.

5. LIFETIME USE 50 YEARS

HDPE has better resistance to UV rays and the environment compared to concrete pipes. HDPE is more suitable for long-term use more than 50 years while concrete pipes may crack when exposed to UV humidity and other environmental impacts.

HDPE has better resistance to UV rays and the environment compared to concrete pipes. HDPE is more suitable for long-term use more than 50 years while concrete pipes may crack when exposed to UV humidity and other environmental impacts.

1. LIGHT WEIGHT

HDPE pipe is lightweight when compared with concrete pipes

HDPE pipe is lightweight when compared with concrete pipes

LIGHT WEIGHT

2. FLEXIBLE AND HIGH LIQUID FLOW

HDPE pipe has good flexibility and easy to install when compared to concrete or reinforced concrete pipes. In addition, the inner surface of the HDPE pipe is smooth, resulting in a high flow rate of water.

HDPE pipe has good flexibility and easy to install when compared to concrete or reinforced concrete pipes. In addition, the inner surface of the HDPE pipe is smooth, resulting in a high flow rate of water.

FLEXIBLE AND HIGH LIQUID FLOW

3. CHEMICAL RESISTANCE AND CORROSION RESISTANCE

HDPE pipes are resistant to chemicals and corrosion when compared with concrete pipes. Therefore HDPE pipes are suitable to use in chemical and acidic environments.

HDPE pipes are resistant to chemicals and corrosion when compared with concrete pipes. Therefore HDPE pipes are suitable to use in chemical and acidic environments.

CHEMICAL RESISTANCE AND CORROSION RESISTANCE

4. ENVIRONMENTAL FRIENDLY

HDPE pipes are considered more environmentally friendly than concrete pipes in many factors like energy consumptions, carbon emissions, resource usage, transportation, installation and its Lifecycle of more than 50 years.

HDPE pipes are considered more environmentally friendly than concrete pipes in many factors like energy consumptions, carbon emissions, resource usage, transportation, installation and its Lifecycle of more than 50 years.

ENVIRONMENTAL FRIENDLY

5. LIFETIME USE 50 YEARS

HDPE has better resistance to UV rays and the environment compared to concrete pipes. HDPE is more suitable for long-term use more than 50 years while concrete pipes may crack when exposed to UV humidity and other environmental impacts.

HDPE has better resistance to UV rays and the environment compared to concrete pipes. HDPE is more suitable for long-term use more than 50 years while concrete pipes may crack when exposed to UV humidity and other environmental impacts.

LIFETIME USE 50 YEARS

LIGHT WEIGHT

FLEXIBLE AND HIGH LIQUID FLOW

CHEMICAL RESISTANCE AND CORROSION RESISTANCE

ENVIRONMENTAL FRIENDLY

LIFETIME USE 50 YEARS

Previous

Next

What makes TAP pipe different from other

100 % High quality raw materials

Advanced Machineries

Certified and controlled production process

High production capacity and supply consistency

Over 39 years of experience

Experienced Logistics team

Previous

Next

FULL EQUIPMENT LABATORY

OVER 39 YEAR OF EXPERIENCE

ADVANCE + HIGH QUALITY MACHINE

EXPERIENCE, QUALIFIED AND PROFESSIONAL INSTALLATION TEAM

Trusted by customers in over 23 countries worldwide.

We offer OEM services to our custommers both locally and internationally

We offer OEM services to our custommers both locally and internationally